Call for projects in DIK

At present there are the following calls for projects:

Cooperation

If you are interested to call together with the DIK a joint project to life, don't hesitate to contact us!

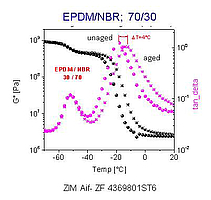

Investigations of the potential of suitable polymer blends on thermal oxidative aging stability of polydienes

Elastomer materials are very important for the production of dynamically high loaded, temperatur- and media resistant products. The life time of elastomer products is depending to a great extend on material homogeneity beside their construction and the mechanical load and chemical exposure during use.

EcoRubber - Simulation-based sustainability assessment of elastomer products and manufacturing processes in the rubber industry

Considering climate protection as one of the most important elements of the EU's "Green Deal", the focus is on climate change and the observed global warming due to the emission of so-called greenhouse

gases (GHG), whereby the emission of CO2 is considered to be the main driver. Accordingly, all emitted gases contributing to global warming with a greenhouse effect (GWP - "global warming potential") are standardised as CO2 equivalents.

Cumulative Damage in Rubber Materials – Benchmark and Further Development

This project is motivated by components loaded in service. These real-life loadings are rarely of continuous cyclic constant amplitude nature. In daily use, rubber components are exposed to all kinds of loadings. However, the lifetime of such components is often predicted using fatigue data from simple test pieces which were exposed to continuous cyclic loads with constant amplitude.

Recycling of thermoplastic end-of-life articles for use in high-temperature and media-resistant thermoplastic elastomers (TPE-V) for applications in the engine compartment of alternative drive concepts

- Increased resource efficiency by using thermoplastic recyclates

- Improved functionality and performance of TPE-V parts

- Increased high-temperature and media stability of TPE-V

- Development of new material combinations