Materials Development and Testing (WE)

Materials Development and Testing forms the link between elastomer research and Industry. Materials development implements the insights gained with respect to focal-point characterization of raw materials, compounds and elastomers as well as processing methods. Making maximum use of numerous physical testing methods, the department is able to develop new materials with specific property profiles.

Proceeding on the basis of the physicochemical properties of raw materials, the department investigates the interaction of these in application-relevant formulas. The functioning of newly developed or modified raw materials is examined on rubber compounds best exemplifying the relevant field systems. This involves, among other things, systematic analysis of the effect on the dispersion behavior of fillers as well as on crosslinking behavior, processibility and storage stability. The insights serve as direct feedback on field-related basic research by making it possible to determine how the micro- and macrostructure of raw materials affect processing and application properties.

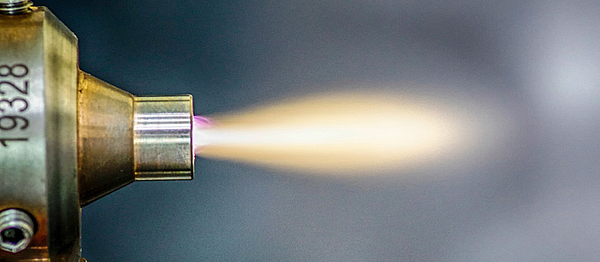

A focal point that has emerged in recent years is material modification by means of atmospheric-pressure plasma treatment aimed at improving permeation density and modifying friction and wetting properties as well as bondability and adhesion.

Head of department

Main research topics

- Development of new materials

- Development of measuring methods

- Physical testing as per standardized methods

- Characterization of the distribution of fillers in rubber compounds

- Vulcanization kinetics

- Influence of polymer and filler structure on processing

- Definition of quality characteristics of new raw materials

- Determination of aging behavior of elastomers under thermal and medial as well as dynamic load, with particular attention given requirements specific to the automotive industry

Call for projects

Rubber-technological evaluation of raw materials

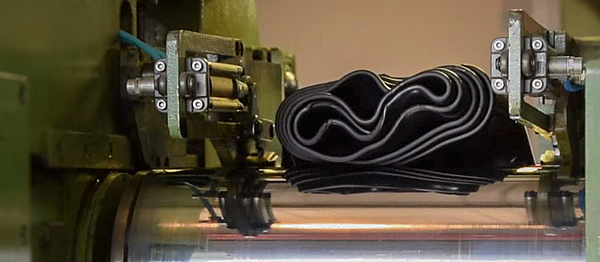

- Evaluating the processability of rubber compounds with standard industrial mixing units (no “laboratory-mixer”)

- Determination of the “in rubber”-properties of raw materials (polymer, filler, rubber powder etc.)

- Metrological detection all relevant compound- and vulcanizate-properties

Modification with atmospheric pressure plasma

- Plasma – „activation“

- Ultra-fine cleaning of substrate surfaces

- Plasma – „polymerization“; Deposition of functional layers on various substrates

- Influence on the properties of rubber (e. g. friction, adhesion and lifetime)

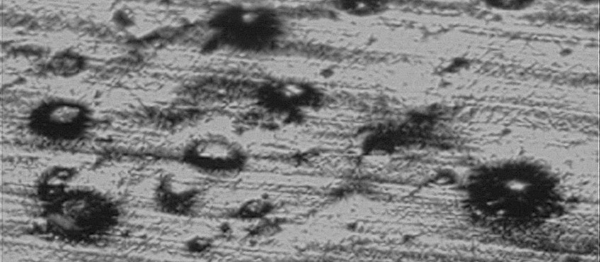

Dispersion-analysis

- Analysis of the dispersion (macro-dispersion) of fillers

- Characterization of the mixed state

- Calculation of the degree of dispersion

- Determination of the aggregate- and agglomerate size distribution

Services

Investigations on compounds (according to valid standards)

- Determination of Mooney viscosity and Mooney scorch time

- Investigation of the vulcanization behavior

- High pressure capillary viscometer (not accredited)

Investigations on vulcanizates (according to valid standards)

- Determination of the stress-strain-behavior

- Hardness (Shore, IRHD)

- Determination of the abrasion

- Analysis of the tear-strength