Elastomer Chemistry

- Characterization of multiphase systems (morphology)

- Polymeric fillers

- Rubber/ filler interaction

- Crosslinking

- Aging mechanisms

- Modification of fillers and polymers

- Nanomaterials (synthetic and bio-based)

- Leachables and extractables out of polymer materials

- Elastomer emissions and environmental exposure

- Transport processes in polymers for gases and fluids in elastomers

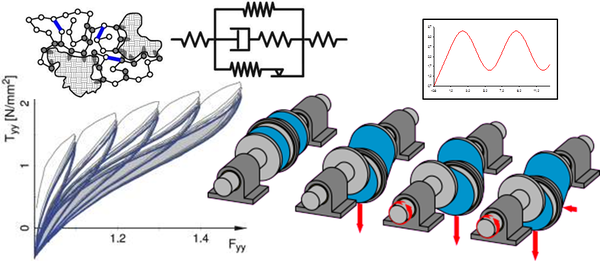

Elastomer Physics

- Lifetime prediction of compounds unter dynamic load

- Fracture mechanics and fatigue

- Contact mechanics and friction

- Special investigations of material homogeneity with X-ray tomography (CT)

- Acoustic damping and friction properties

- Dynamical mechanical properties up to high frequencies

- Magnetorheological elastomers for sensor technology and adaptive systems

Material Concepts and Modeling

- Friction and wear

- Polymer networks and blends

- Fillers and reinforcement

- Dielectric spectroscopy

- Dynamic-mechanical analysis

- Rheology of rubber melts

Simulation and Continuum Mechanics

- Problem based material models for e.g. filled elastomers, thermoplasts, TPVs, foamed materials (under consideration of the Mullins and Payne effect, material damping and anisotropy)

- Implementation of novel material model concepts in commercial FE programs e.g. Abaqus, MSC.Marc

- Parameter identification via homogeneous and inhomogeneous load distribution

- Simulation of fatigue and ageing processes

- Material damping and anisotropy

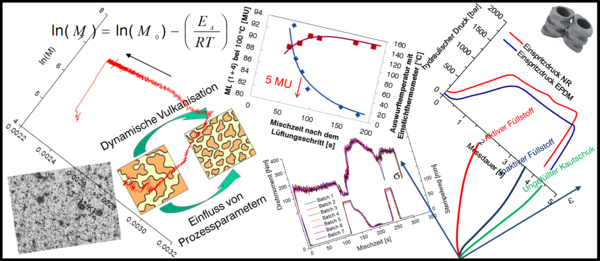

Processing Methodology

- Additive manufacturing of elastomer parts based on filled rubber compounds

- Direct bonding of 2-component parts using 2K-injection moulding

- Thermally optimized rubber injection moulding

- Thermoplastic elastomers (TPVs) based on dynamic vulcanization processes

- Investigation of mixing efficiency regarding distributive mixing using Laser-Induced-Breakdown-Spectroscopy

- Recycling strategies / devulcanization of rubber powder

Materials Development and Testing

- Development of new materials

- Development of measuring methods

- Physical testing as per standardized methods

- Characterization of the distribution of fillers in rubber compounds

- Vulcanization kinetics

- Influence of polymer and filler structure on processing

- Definition of quality characteristics of new raw materials

- Determination of aging behavior of elastomers under thermal and medial as well as dynamic load, with particular attention given requirements specific to the automotive industry